Our Technology is your Path to Profitability

Raj Engineering is involved in manufacturing of precision machined components, Products catering to both Domestic and International markets in the fields of Defence, Aerospace, Railways , Automotive, Medical Devices, Oil & Gas Industry, Energy, Die & Mould ,Heavy Engineering.

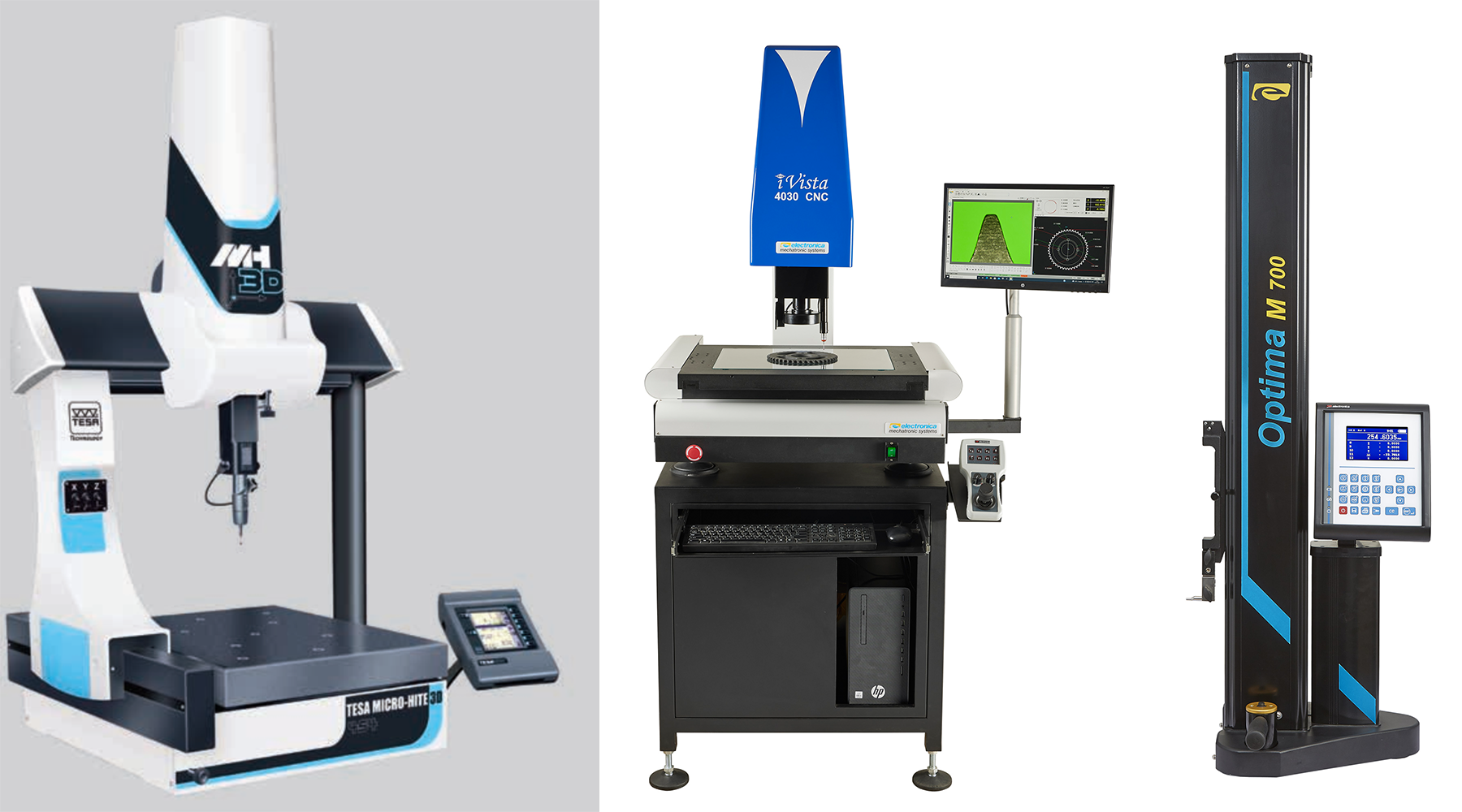

Raj Engineering has created a world class infrastructure, for manufacturing as well as inspection, testing & quality control.

We follow ethical business practices as one of the prime driver of success which reflects in our rewards & achievements.

Our Mission

To Be a Business Partner, Who is committed to comply by Quality, Who can Provide COST effective solutions, Who strongly believes in operating on the fundamentals of ETHICAL business.

Our Vision

Raj Engineering aims to be the most preferred organization for Domestic & International Engineering and Automobile industry.

Best Quality Assurance in Business

Numerical control (NC) (also computer numerical control (CNC)) is the automated control of machining tools (drills, boring tools, lathes) and 3D printers by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following a coded programmed instruction and without a manual operator. CNC is highly automated, so is price competitive for high quality one off parts and mid to high volume production CNC allows almost any material to be used. CNC Mills are very common and can be used for many geometries.

Manufacturers are leaders in making vital products in the industry, such as jet engines, helicopters, and submarines. And recent advancements in technology, gone are the days of gritty factory life. Workers today use their machining skills in a clean, professional setting with advanced and cutting-edge technology. While the CNC machining process offers various capabilities and operations, the process remain largely the same throughout all of them. When specifying parts to a machine shop, it's important to include any tolerances. Though CNC machines are very accurate, they leave some slight variation between duplicates of the same part.

Select the appropriate tool according to the programming list. Before installing the tool, clean the tool head and nozzle completely. After installing the tool, use a calibration to check. After the knife is copied, check it from the start to prevent the right knife from being wrong and the number of copies will cause major losses. After confirming that everything is normal, adjust it to an appropriate speed and start processing. During the machining process, take time to investigate whether the machining is abnormal, the knife is not worn, and if the tool is worn, the sharpening should be suspended to ensure that the machine is normal.

Stainless steel is highly resistant to corrosion and rust, making it suitable for situations where a part may be exposed to the elements for a long period of time. Stainless steel is also fairly malleable and ductile. Multiple stainless steel alloys, including a food-safe variety. They are not heat-treatable except by cold working, and are generally non-magnetic.

Our product range includes a wide range of SS Automobile Bush, Stainless Steel Precision Shafts, SS Mechanical Flange, Stainless Steel Male Bush, Stainless Steel Threaded Flanges and Stainless Steel Round Flange.

Functionality blended into a Synchronous system

Domestic Clients

International Clients

Hear From Our Happy Customers

“It has been a very good experience working with your guys. He has always assisted me over the phone for any problems that have arisen, even on weekends. He has been a great resource for us and I hope we continue rebuilding controls with your company.”

“Thank you very much for all the support we got from RAJ Engineering this year. We are very pleased with the outcome, the machine works exactly as we were expecting.” Thanks for being on time and much appreciated. We are proud to be partnering up with you."

I observe the way you organize your company and how your employees love working there. I am very impressed. I am modelling my company the same way. I would recommend your company to anyone looking to build a relationship with a quality organization."